Super piper cub 95 build

-

Phugoid

- Posts: 952

- Joined: Wed Jan 20, 2010 8:17 am

You'll still need left rudder. The wash out I described will want to make it fly right otherwise......

Glue the rudder on nice and sqaure at this point, you can add rudder adjustment once the model is complete by adding an acetate tab, which is exactly what I did, I'll take a picture later to show you what I mean.

Glue the rudder on nice and sqaure at this point, you can add rudder adjustment once the model is complete by adding an acetate tab, which is exactly what I did, I'll take a picture later to show you what I mean.

-

Phugoid

- Posts: 952

- Joined: Wed Jan 20, 2010 8:17 am

-

ADW 123

- Posts: 1158

- Joined: Mon Feb 22, 2010 5:22 pm

- Location: Cincinnati, Ohio

-

Phugoid

- Posts: 952

- Joined: Wed Jan 20, 2010 8:17 am

I couldn't take pictures of my cub as it's now hanging from the lampshade in my daughters room and she is asleep!

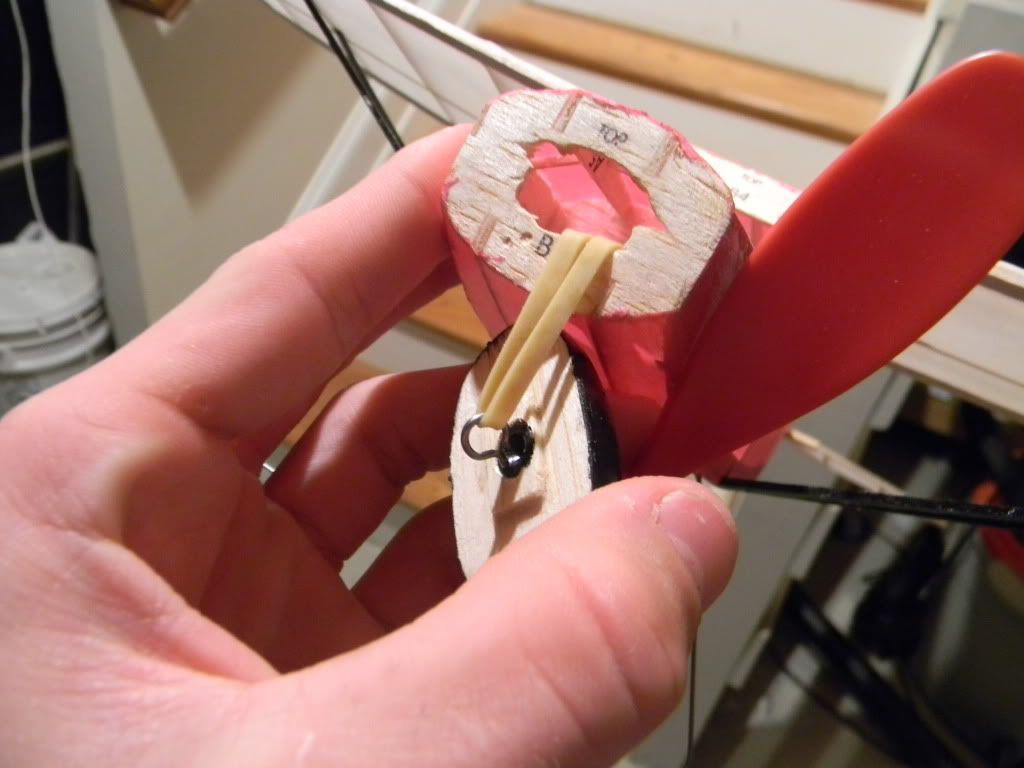

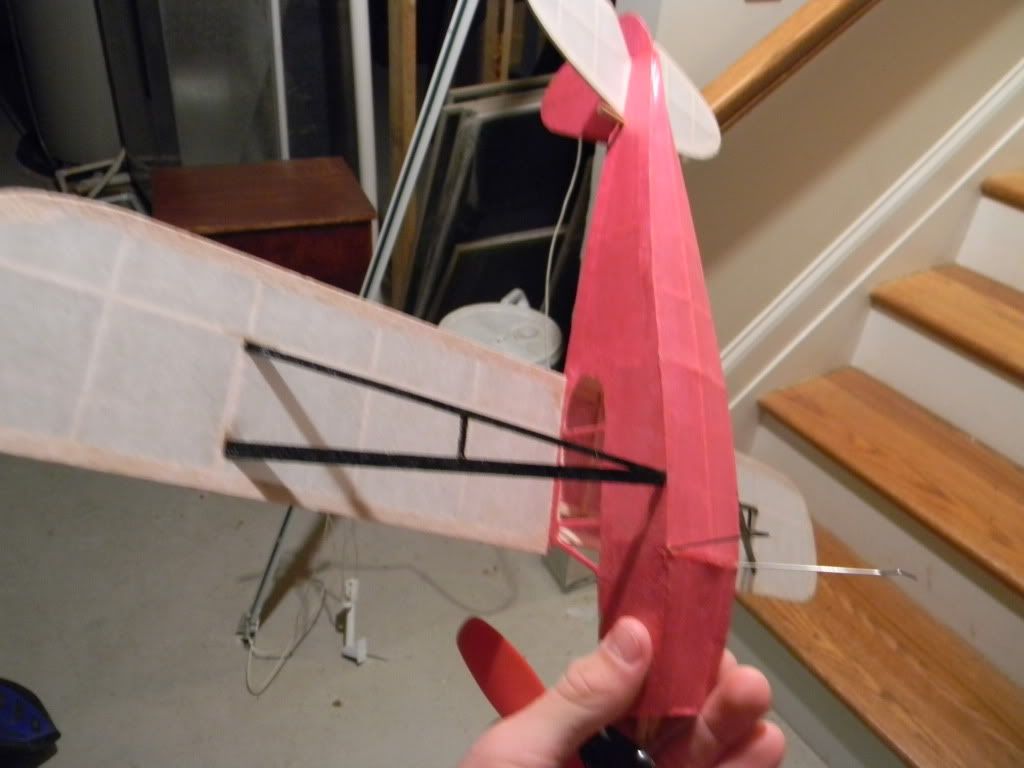

These are pictures of my Hellcat instead... These are tabs made from clear acetate sheet. You can bend them to give a left turn if on the fin, or to give more lift to one wing or the other to balance things out when the model turns......

I use castor oil as lube generally. I am also trialing some silicone compound, as it does not spatter or stain the tissue.

These are pictures of my Hellcat instead... These are tabs made from clear acetate sheet. You can bend them to give a left turn if on the fin, or to give more lift to one wing or the other to balance things out when the model turns......

I use castor oil as lube generally. I am also trialing some silicone compound, as it does not spatter or stain the tissue.

-

ADW 123

- Posts: 1158

- Joined: Mon Feb 22, 2010 5:22 pm

- Location: Cincinnati, Ohio

-

Phugoid

- Posts: 952

- Joined: Wed Jan 20, 2010 8:17 am

The KP aero winder is great. If you are short of cash, and or time you can use an old fasioned type hand drill, but they always have an odd ratio (to even out gear wear), so you have to be good at mental arithmatic to work out the winds!

If you use an old drill then DO NOT hold a winding hook in the chuck, if the hook comes out during winding it will smash your nice model to matchwood. Instead cross drill the spindle and make a stiff wire hook that passes through the holes and is nice and secure.

If you use an old drill then DO NOT hold a winding hook in the chuck, if the hook comes out during winding it will smash your nice model to matchwood. Instead cross drill the spindle and make a stiff wire hook that passes through the holes and is nice and secure.

-

ADW 123

- Posts: 1158

- Joined: Mon Feb 22, 2010 5:22 pm

- Location: Cincinnati, Ohio

i already investigated a drill. i used an electric one. but it would break the rubber because of too many winds in it. ive been looking at the KP 15:1 winder, about 20 bucks. its one of those things ill just have to suck it up and dish out the cash for it as im sure ill use it all the time and it will be very helpful. i used to just wind it with my finger.... somthing easier said than done, and it takes forever. would a wider strip of rubber give me more winds than a skinny one?